Mastering Multi-Color 3D Printing with a Single Extruder Using Filament Swaps

Multi-color 3D printing adds vibrant, eye-catching details to prototypes, models, and functional parts, but many hobbyists and small-scale prototypers rely on single-extruder 3D printers, which typically extrude only one filament at a time. By mastering 3D printer filament swapping—pausing the print to change filament colors mid-process—you can achieve stunning multi-color results without needing an expensive dual-extruder setup. This guide provides a step-by-step approach to performing filament swaps, optimizing slicer settings, and troubleshooting common issues to create professional-quality multi-color prints with a single-extruder 3D printer.

Why Use Filament Swaps for Multi-Color Printing?

Filament swapping allows you to introduce multiple colors in a single 3D printer print by manually or automatically pausing the print and replacing the filament with a different color. This technique is ideal for creating layered designs, such as logos, decorative models, or prototypes with distinct color-coded sections. It’s cost-effective, leverages existing equipment, and offers creative flexibility for small-scale projects. The key is to plan the print carefully, configure your slicer software, and execute swaps precisely to ensure seamless transitions.

Step 1: Designing for Filament Swaps

Start by designing or selecting a model suited for filament swapping. Models with distinct layers or sections work best, as color changes typically occur at specific layer heights. For example, a model with a base in one color and a logo or top section in another is ideal. Use 3D modeling software like Tinkercad, Fusion 360, or Blender to split your design into segments where color changes will occur. Ensure each segment aligns with a layer height for clean transitions.

If you’re using a pre-existing STL file, check that it has clear layer boundaries for color changes. For complex designs, consider splitting the model into multiple parts that can be printed separately and assembled later to simplify the swapping process. Keep the design’s layer height in mind, as thinner layers (e.g., 0.1–0.2 mm) provide more precise control over where color changes occur.

Step 2: Configuring Slicer Settings

Your slicer software (e.g., Cura, PrusaSlicer, or Simplify3D) is critical for automating filament swaps. Most slicers have a built-in feature to pause the print at specific layer heights, allowing you to change filament. Follow these steps to set up your slicer:

- Load the Model: Import your 3D model into the slicer and set basic parameters like layer height (e.g., 0.2 mm) and print speed (e.g., 40–50 mm/s for PLA).

- Identify Swap Points: Preview the sliced model layer by layer to determine where color changes should occur. Note the exact layer numbers for each transition.

- Add Pause Commands: In Cura, use the “Extensions > Post Processing > Modify G-Code” menu to add a “Filament Change” or “Pause at Height” script. In PrusaSlicer, use the “Custom G-code” option at specific layer heights. Set the pause at the desired layer, ensuring the printer moves the printhead away from the model to avoid oozing.

- Adjust Retraction: Increase retraction distance (e.g., 1–2 mm for direct-drive extruders, 3–5 mm for Bowden) and speed (e.g., 30–40 mm/s) before the pause to prevent stringing during the swap.

- Save the G-Code: Generate the G-code file with the pause commands embedded and save it to your printer’s SD card or transfer it via USB.

Test the settings with a small model, like a 20mm cube with a color change at 10 mm height, to ensure the pause occurs correctly.

See also: Navigating Complex Regulations with AI: How Modern Tech is Reshaping Compliance

Step 3: Performing the Filament Swap

When the printer pauses at the designated layer, follow these steps to swap filament:

- Prepare the New Filament: Cut the tip of the new filament at a 45-degree angle for smooth insertion. Ensure it’s the same material type (e.g., PLA to PLA) to avoid compatibility issues.

- Unload the Current Filament: Use the printer’s interface to unload the current filament, or manually extrude and pull it out if the pause command doesn’t include unloading. Be cautious, as the nozzle will be hot (typically 200–220°C for PLA).

- Load the New Filament: Feed the new filament into the extruder until it extrudes consistently from the nozzle. Purge a small amount (5–10 mm) to clear residual material from the previous color.

- Resume Printing: Once the new filament is loaded, resume the print via the printer’s interface. Watch the first few layers after the swap to ensure proper extrusion and adhesion.

For multiple color changes, repeat this process at each pause. Practice with a simple model to perfect your timing and technique.

Step 4: Optimizing Color Transitions

To achieve clean color transitions, fine-tune your settings based on test prints. Common issues include:

- Stringing or Oozing: If the new color leaves strings, increase retraction distance or enable “wipe” features in the slicer to clean the nozzle before moving.

- Layer Adhesion Issues: If layers don’t bond well after a swap, slightly increase the nozzle temperature (e.g., 5°C) for the first few layers of the new color to improve adhesion.

- Color Bleeding: If colors mix at the transition, purge more filament during the swap or add a “purge tower” (a small printed structure that clears the nozzle) in your slicer settings.

Print a test model with multiple color changes, such as a layered keychain or a segmented cube, to evaluate transitions. Adjust retraction, temperature, or purge settings based on the results.

Step 5: Post-Processing for a Polished Look

After printing, enhance the model’s appearance with post-processing. Sand rough transitions with fine-grit sandpaper (e.g., 400–800 grit) to smooth layer lines. For glossy finishes, apply a clear coat or polish PLA with a microfiber cloth. If the model has small imperfections at color boundaries, use a craft knife to trim excess material. For functional prototypes, test the part’s strength to ensure swaps didn’t compromise structural integrity.

Practical Tips for Success

- Use Compatible Filaments: Stick to the same filament type (e.g., all PLA) to ensure consistent melting points and adhesion. Mixing materials like PLA and ABS can cause issues.

- Test Small Models First: Practice with simple designs to minimize filament waste while learning the process.

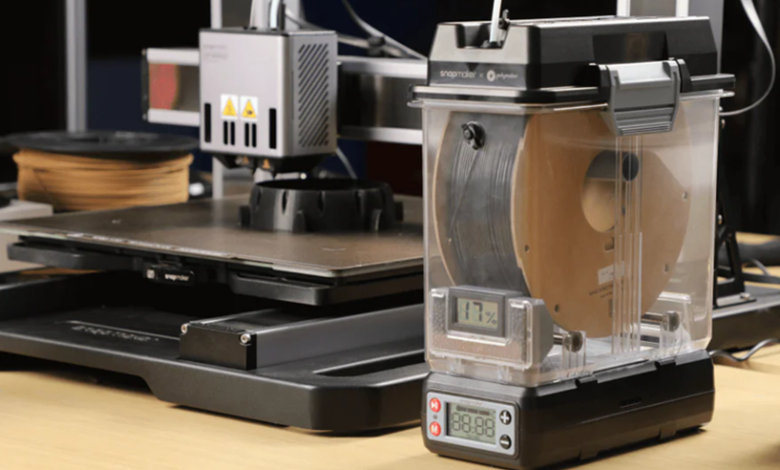

- Keep Filament Dry: Store filaments in sealed containers with desiccants to prevent moisture-related issues like bubbling during swaps.

- Automate Where Possible: Use a filament runout sensor if your printer supports it to streamline unloading and loading.

- Document Settings: Record successful slicer settings and layer heights for each project to replicate results.

Benefits and Applications

Filament swapping enables vibrant, multi-color prototypes without investing in a dual-extruder printer, saving hundreds of dollars. It’s ideal for creating visually appealing models like custom keychains, educational tools with color-coded parts, or artistic sculptures. For small-scale prototyping, it allows you to highlight functional sections (e.g., hinges or buttons) in different colors for clarity during testing or presentations.

Challenges and Solutions

Filament swaps can be time-consuming, especially for models with frequent color changes. To save time, group color changes into fewer pauses by designing models with larger single-color sections. Another challenge is slight layer misalignment after pausing, which can be mitigated by ensuring the print bed remains stable and the printhead parks correctly during swaps. If your printer resumes in the wrong position, double-check the G-code for proper coordinates or update your firmware.

Conclusion

Mastering multi-color 3D printing with filament swaps transforms a single-extruder printer into a versatile tool for creating stunning, professional-quality prints. By carefully designing models, configuring slicer settings, and executing precise filament changes, you can achieve clean color transitions and vibrant results. Start with small test prints, refine your technique, and experiment with creative designs to unlock the full potential of this cost-effective method. With practice, filament swapping will become a seamless part of your 3D printing workflow, adding color and flair to your prototypes and models.