Heat Sink Material Guide for Efficient Thermal Management

Effective thermal management starts with selecting the most suitable heat sink material for your needs. The right choice can significantly improve heat dissipation, protect components from overheating, and extend the lifespan of your devices. Materials like aluminum and copper dominate the market, each offering distinct benefits in terms of conductivity, weight, and cost.

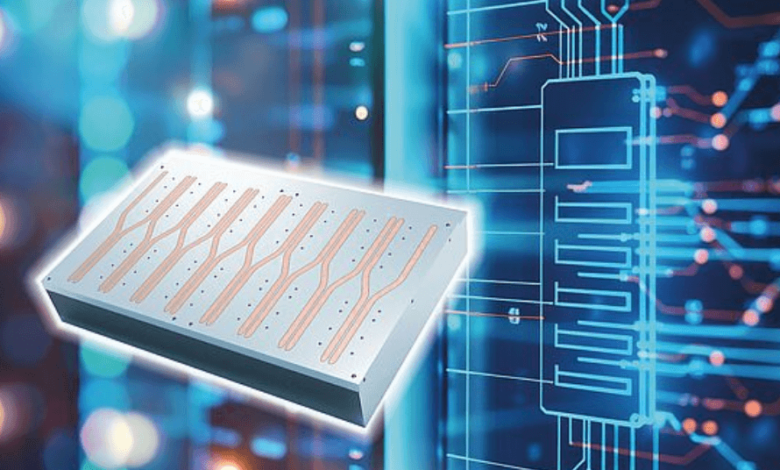

In this heat sink material guide for efficient thermal management, we will cover the key properties, advantages, and applications of each option to help you make the best decision for optimal performance.

Key Properties of Heat Sink Materials

1. Thermal Conductivity and Heat Dissipation

This property measures how efficiently a material can transfer heat away from electronic components, helping prevent overheating and maintain optimal performance.

Key Materials:

- Copper: Transfers heat very efficiently (~400 W/m·K), keeping high-performance devices like gaming PCs, AI servers, and power electronics cool. However, it is heavy and more expensive.

- Aluminum: Has good heat transfer (~237 W/m·K), enough for most everyday electronics. It balances cooling, cost, and weight, making it ideal for laptops, LED lights, and portable devices.

Efficient thermal conductivity ensures that components operate safely, reliably, and at peak performance.

2. Weight and Density

How heavy a heat sink material is affects the total weight of a device. This matters most for portable electronics, aerospace equipment, or any situation where keeping weight low is important.

Key Materials:

- Copper: Heavy and dense, copper adds a lot of weight, making it better for stationary or heavy-duty devices like servers, industrial machines, or high-performance desktops.

- Aluminum: Lighter and less dense, aluminum keeps devices portable and easy to carry. It’s ideal for laptops, smartphones, tablets, and other weight-sensitive electronics.

Choosing the right material based on weight ensures devices are both functional and user-friendly, especially for portable or weight-sensitive applications.

3. Cost and Availability

The cost and availability of a heat sink material directly influence manufacturing expenses and how easily the material can be sourced. Choosing the right material helps manage production budgets and ensures a steady supply for manufacturing.

Key Materials:

- Copper: High cost makes it more expensive to use in devices, which can increase the overall price of the product. Its sourcing may also be more limited compared to aluminum.

- Aluminum: Lower cost and wide availability make aluminum a practical choice for mass-produced electronics. It keeps production costs down while still providing effective cooling.

Considering cost and availability helps manufacturers balance performance, affordability, and supply chain reliability.

4. Corrosion Resistance and Durability

These factors determine how long a heat sink will last, especially in harsh, humid, or outdoor environments. A durable, corrosion-resistant material ensures reliable cooling over the device’s lifetime and reduces maintenance or replacement costs.

Key Materials:

- Copper: Naturally resistant to corrosion and highly durable, making it ideal for long-lasting, high-performance applications.

- Aluminum: Can corrode over time, but anodizing (a protective surface treatment) improves its corrosion resistance and durability, making it suitable for most consumer and industrial electronics.

Choosing a material with good corrosion resistance and durability helps maintain consistent thermal performance and extends the device’s lifespan.

See also: Best Smartwatches for Women: Style Meets Tech

5. Manufacturability and Design Flexibility

This measures how easily a heat sink material can be shaped and produced, affecting cost and design options.

Key Materials:

- Copper: Harder to machine, can increase manufacturing cost.

- Aluminum: Easier to extrude and shape, allowing complex designs at lower cost.

Choosing a material with good manufacturability allows for efficient production and more flexible, optimized heat sink designs.

Common Heat Sink Materials and Their Characteristics

1. Aluminum

Advantages:

- Lightweight: Low density (~2.7 g/cm³), great for portable and compact devices.

- Cost-Effective: Costs 50–70% less than copper, ideal for mass production.

- Corrosion-Resistant: Forms a natural oxide layer that protects it.

- Good Thermal Conductivity: Around 237 W/m·K, suitable for many applications.

Limitations:

- Lower Thermal Conductivity: Transfers heat about 60% less efficiently than copper.

- Mechanical Strength: Not as strong as some other materials in certain conditions.

Typical Applications: Consumer electronics like laptops, smartphones, and LED lights typically use standard cooling solutions.

2. Copper

Advantages:

- Excellent Thermal Conductivity: Transfers heat very efficiently at about 400 W/m·K, making it ideal for high-performance applications.

- Durable: Strong and long lasting, able to resist corrosion and handle high temperatures without degrading.

Limitations:

- Heavier: Due to its high density, it adds significant weight, making it less ideal for portable or lightweight devices.

- Costly: Higher in price compared to aluminum, increasing overall material and manufacturing costs.

- Harder to Machine: Requires more effort and specialized tools to shape, making manufacturing more complex and time consuming.

Typical Applications: High-performance electronics and industrial machines need efficient cooling to prevent overheating.

Factors to Consider When Choosing a Heat Sink Material

- Heat Load and Thermal Resistance

Select a heat sink by considering the component’s heat output (watts) and the heat sink’s thermal resistance. A lower thermal resistance indicates more efficient heat dissipation and better cooling performance.

2. Physical Space and Weight

Consider the space available inside the device and its weight limits. Compact devices may require specially shaped heat sinks to fit properly, and using lightweight materials like aluminum is ideal for portable or low-weight gadgets.

3. Budget and Cost-Effectiveness

Select materials that offer a good balance of cost and performance. Aluminum is affordable and easy to manufacture, while copper provides superior cooling but at a higher cost. Using high-quality materials can reduce the need for additional cooling and help extend the lifespan of your devices.

4. Environmental Conditions and Reliability

- Ambient Temperature: Ensure the material can handle the operating temperature of the device.

- Corrosion Resistance: Aluminum naturally resists corrosion, while copper may need protective coatings in humid or harsh environments.

- Mechanical Strength: Copper is stronger but heavier; choose materials based on the mechanical stresses the heat sink will face.

Consider the device’s heat, cooling needs, size, weight, cost, environment, and materials to choose a heat sink that keeps it working well.

Material Selection Recommendations

1. Matching Material to Application

- High-Performance Applications: For gaming PCs, AI servers, or high-power electronics, materials with excellent heat transfer are essential. Copper is ideal due to its superior thermal conductivity.

- General-Purpose Applications: Aluminum is an affordable and effective cooling choice for everyday electronics, LEDs, and moderate-power devices.

2. Trade-offs Between Cost, Weight, and Efficiency

- Copper: Excellent heat transfer, but heavy and expensive. Best for applications where performance is the priority over weight or cost.

- Aluminum: Balances cooling performance, weight, and cost. Suitable for most consumer electronics and medium-power applications.

- Graphite and Composite Materials: Lightweight with good thermal performance, though often more expensive. Ideal for specialized or weight-sensitive designs.

3. Emerging Trends and Innovations

- Carbon Nanotube Pads: These pads transfer heat more effectively than regular thermal pastes, helping electronics stay cooler.

- Advanced Manufacturing: 3D printing and CNC machining enable complex heat sink designs for enhanced heat dissipation and customization.

- Phase-Change Materials (PCMs): These materials absorb heat as they melt and release it as they solidify, helping devices stay cool and manage thermal energy more efficiently.

Select a heat sink material based on your device’s cooling requirements, size, weight, cost, environmental conditions, and performance goals.